Don't miss our holiday offer - up to 50% OFF!

10 Best Clothing Manufacturering in China

10 Best Clothing Manufacturering in China

China holds a significant position in the global textile and apparel industry, leveraging its large-scale exports to markets in Asia, Europe, and North America. The apparel production cluster, centered around the five eastern coastal provinces, forms a crucial pillar of the industry’s supply chain.

China’s clothing manufacturing industry covers a wide range of categories, including daily casual wear and professional attire, as well as various tailored and sewn products, including accessories such as handbags, hats, shoes and briefcases, forming a broad and segmented product matrix.

Relying on a complete industrial chain support and efficient supporting system,clothing manufacturers in China can provide stable and reliable production capacity support to their partner companies, helping them seize the growth opportunities continuously released by the global market.

ZENITH-Best Women Clothing Manufacturer in China

AEL Apparel – Best Sustainable & Eco-Friendly Manufacturer

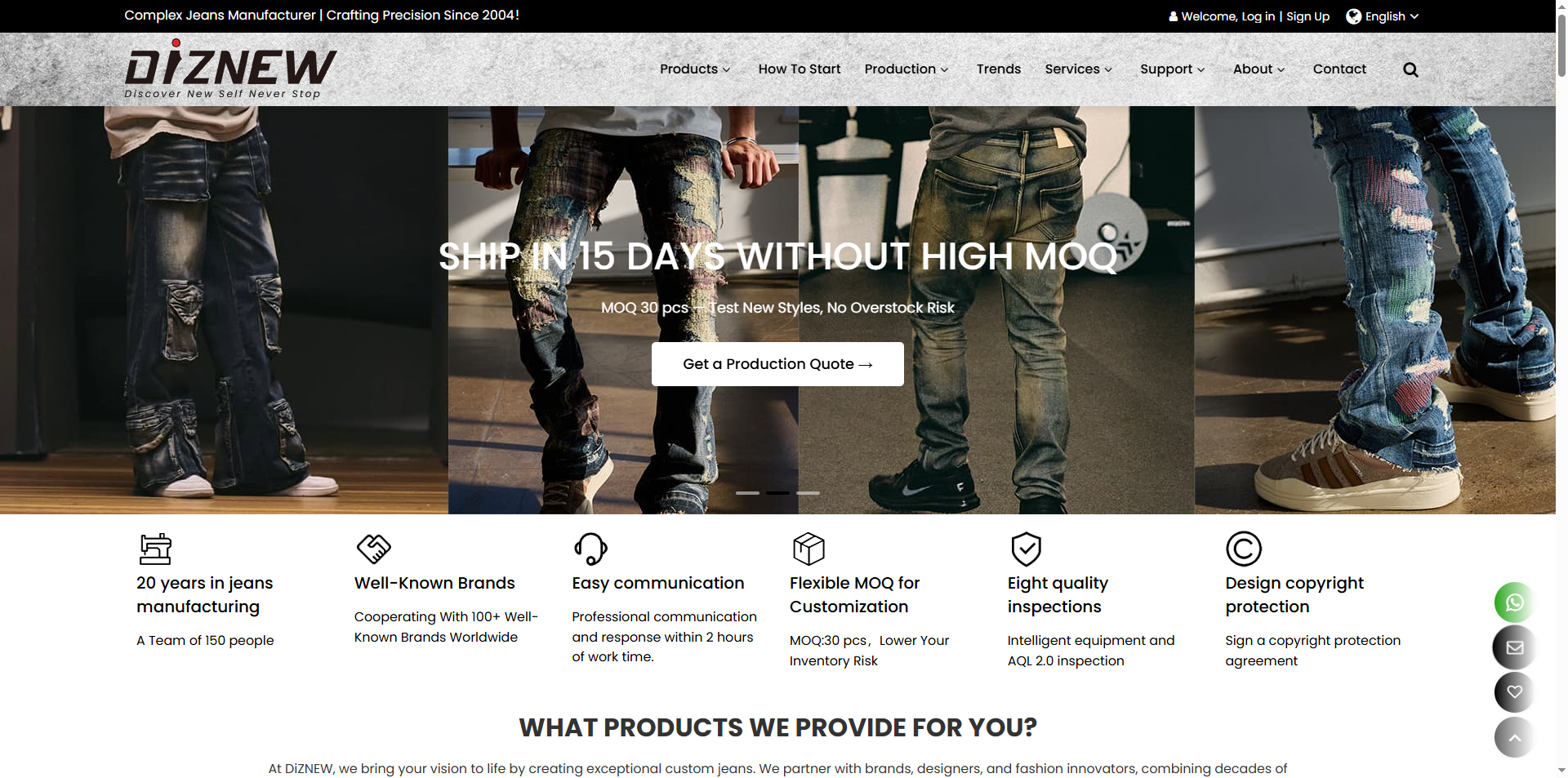

Diznew – Best Denim Clothing Manufacturer in China

Hu Join Apparel – Best for Fashion-Forward Private Label

Ning How Apparel – Best for Startup & Small-Batch Orders

Appareify – Best Overall Clothing Manufacturer in China

Motoboy – Best for Motorcycle Protective Apparel

Pattern Solution – Best for Custom Women’s Apparel

Changda Garment – Best for OEM/ODM Export to Europe

Yotex Apparel – Best for Functional Outdoor Apparel

Here are some of the best manufacturers you can pick from.

1.ZENITH-Best Women Clothing Manufacturer in China

ZENITH is a top Chinese clothing manufacturer, exporting high-quality garments to Europe, North America, and Australia. With a monthly production capacity of 200,000 pieces, ZENITH is one of the most outstanding clothing manufacturers in China.

At ZENITH, every garment is produced with a focus on meeting the buyer’s specific requirements. Clients can personalize their garments through the company’s private bespoke service, which includes customizing the color and fabric of the garment, as well as adding their own brand logos and labels. ZENITH also offers contract manufacturing services, bringing clients’ design concepts to life.

ZENITH offers a 3-7 day production cycle for custom-made clothing designs, while custom designs have a 20-30 day production cycle. ZENITH has a dedicated team to ensure efficient communication. Furthermore, they prioritize ethical practices to ensure greater sustainability and fair labor conditions. They promote eco-friendly development concepts and work with their clients to build a healthy and environmentally friendly environment.

Main Products:

Full range of clothing customization, covering women’s clothing, ladies’ dresses, sportswear, etc., supporting private label customization, such as color, fabric, logo, tag, packaging and other personalized needs.

Advantages:

- Fast and professional production capabilities

- Guaranteed ideal production lead times

- Customized services available

- Eco-friendly and sustainable production methods

- A professional team provides stable support

Disadvantages:

Since the factory is in China, factory inspections and quality control may be a problem.

2.AEL Apparel – Best Sustainable & Eco-Friendly Manufacturer

From its inception, this China-based clothing manufacturer has been committed to creating high-quality products with an environmentally friendly approach, an emphasis on innovation, and technology. With a wide selection of private label and custom clothing, AEL Apparel is well-suited to help any customer build their dream clothing line.

This China clothing manufacturer offers styles for men, women, and children. With fast production, customers typically receive their orders within 7 to 20 days, depending on the item ordered.

Main Products:

A full range of apparel, including T-shirts, casual wear, jeans, and children’s clothing, with a core focus on custom apparel made from environmentally friendly fabrics.

Advantages:

They utilize environmentally friendly materials and craftsmanship throughout their entire process, complying with GOTS international certification.

Delivery efficiency is exceptional, with regular orders completed within 7-20 business days and urgent orders delivered within 3 days.

A wealth of customization options are available, allowing for comprehensive personalization, from fabrics to craftsmanship.

Disadvantages:

Environmentally friendly materials are expensive, and product prices are 15%-20% higher than those of regular manufacturers.

Overseas delivery relies on third-party logistics, and delivery times to some remote areas can exceed one month.

3.Diznew – Best Denim Clothing Manufacturer in China

Affiliated to Dongguan Xiaofeiniu Garment Co., Ltd., it has 20 years of experience in denim apparel production and is a leading manufacturer specializing in high-end custom denim. The factory covers an area of 4,000 square meters and launches more than 600 new designs every month. It has appeared at the DAX trade show in Chicago, USA, and serves more than 3,000 American designers.

Main Products:

A full line of denim apparel, including vintage slim-fit jeans, durable denim jackets, and washed denim skirts. Available in 12 washes, including snowflake, ferment, and monkey wash, the fabrics are primarily 11-13oz high-quality cotton-spandex blends.

Advantages:

Strong Customization Flexibility: Minimum order quantities start as low as 30 pieces, supporting full customization of logos, packaging, and graphics. Samples can be completed within 7 days.

Leading Craftsmanship: We blend modern techniques like embroidery and tie-dye with traditional tailoring. Each batch undergoes triple quality inspection and meets AZO environmental standards.

Excellent International Adaptability: With extensive experience in the European and American markets and familiarity with high street and vintage trends, we have provided ODM services to numerous international designer brands.

Disadvantages:

Long delivery times: Orders under 100 pieces take 35 days to deliver, far exceeding the industry average.

Limitation of a single product category: Focusing solely on denim, it cannot meet the one-stop purchasing needs of brands across multiple categories.

4.Hu Join Apparel – Best for Fashion-Forward Private Label

A Suzhou-based fashion apparel manufacturer specializing in small-batch customization and wholesale, with a staff size of 11-50 people. Positioning itself as a “fashion dream incubator,” it focuses on sustainable design and personalized private label services.

Main Products:

Adult fashion and casual wear, including women’s windbreakers, commuter shirts, knitted jackets, etc., mainly using environmentally friendly fabrics such as organic cotton and recycled polyester, and the designs are mainly timeless classics.

Advantages:

Low minimum order quantity: With the exception of specialized categories like sweaters and denim, most products support small-batch customization, significantly reducing the cost of trial and error for startup brands.

Strong sustainability: Utilizing eco-friendly fabrics and ethical production processes, we align with sustainable consumption trends in the European and American markets.

Strong design execution: We can quickly translate client inspiration into finished products, meticulously controlling details (such as pocket layout and specialized closures).

Disadvantages:

Limited production capacity: Delivery capacity is insufficient for batch orders exceeding 1,000 pieces, lacking the advantages of large-scale production.

Weak international service: The independent website lacks multilingual support and cross-border logistics solutions, resulting in high communication costs for overseas customers.

5.Ning How Apparel – Best for Startup & Small-Batch Orders

A local Shenzhen clothing manufacturer specializing in small-batch customization, it serves start-up brands, internet celebrity brands, and small and medium-sized enterprises. It is a popular OEM partner in the cross-border e-commerce field, focusing on the “full-process OEM support” model.

Main Products:

Custom casual apparel, including polo shirts, hoodies, cotton T-shirts, beachwear, basic sportswear, etc., supporting fabric selection and pattern adjustment.

Advantages:

Minimum trial and error costs: Minimum order quantities start as low as 100 pieces per design, and proofing can be completed in 5-7 days, perfect for brands’ initial testing needs.

Comprehensive cross-border services: We offer DDP/PPD duty-paid delivery to address US tariffs, with customs clearance and tariffs handled to avoid additional costs.

Comprehensive supporting services: We offer full-service support, including fabric sourcing, technical packaging, and label production, eliminating the need for clients to connect with multiple resources.

Disadvantages:

Insufficient high-end capabilities: Fabrics primarily consist of mid- to low-end, cost-effective materials, with limited options for high-end functional fabrics.

Mass delivery delays: Delivery times for orders over 100,000 pieces have been extended to over 30 days, failing to meet demand during the brand’s explosive growth period.

6.Appareify – Best Overall Clothing Manufacturer in China

A leading integrated apparel manufacturer in China, we specialize in providing high-quality OEM/ODM services to global DTC brands and startups. With a monthly production capacity of 400,000 pieces, we operate across multiple markets in Asia, Europe, and the US, emphasizing ethical production and sustainable development.

Main Products:

Full-category clothing customization, covering men’s and women’s clothing, children’s clothing, sports and leisure wear, etc., supporting full-dimensional private label customization such as color, fabric, and logo.

Advantages:

Efficiency and scale: Private label orders are delivered in 10-15 days, and custom designs are completed in up to 45 days. Our production capacity accommodates orders from small batches to large-scale orders.

Complete compliance: Fair labor conditions certified, environmentally friendly production processes are employed, and we meet the ethical standards of international brands.

Smooth cross-border communication: A dedicated international account team is available to address language barriers and miscommunication.

Disadvantages:

High on-site inspection costs: The factory is located in China, so overseas customers must bear the travel costs for factory inspections, and the trust-building process takes a long time.

Limited access to small orders: We have limited flexibility in accepting personalized orders of under 100 pieces.

7.Motoboy – Best for Motorcycle Protective Apparel

Tai’an Dongsheng Garment is a professional motorcycle clothing manufacturer that has been deeply engaged in the field of protective functional clothing for many years and focuses on providing OEM services to global cycling equipment brands. Its products use “balance of safety and comfort” as the core selling point.

Main Products:

motorcycle riding clothes, anti-fall jackets, wear-resistant riding pants, protective gloves, etc. The core material is made of high wear-resistant Kevlar fiber fabric.

Advantages:

Excellent Protection: This product meets international safety standards, and the fabric’s tear resistance and impact resistance rival those of leading international brands.

Adaptable: This product combines waterproofing with breathability to meet the needs of cycling in various climates.

Customizable: Details such as protection level, reflective strip placement, and pocket layout can be adjusted to meet customer needs.

Disadvantages:

Narrow application scenarios: Focused solely on cycling equipment, it’s unable to serve mass-market apparel brands.

Low internationalization: The independent website only supports Chinese and English, and payment methods don’t cover mainstream currencies like the Euro and British Pound.

8.Pattern Solution – Best for Custom Women’s Apparel

Founded in 2009 in Shanghai, this expert in women’s clothing customization has 20 years of experience in overseas OEM. Its core customers are from the European, American and Canadian markets. It mainly operates in the CMT (customized manufacturing) and FPP (full package of labor and materials) dual modes.

Main Products:

Customized women’s clothing, including dresses, commuter shirts, knitted jackets, windbreakers, etc., focusing on the optimization of the version for European and American women’s body types.

Advantages:

Precise Pattern Control: In-depth research into the physiques of European and American women ensures tailoring details and sizing far exceed the industry average.

Flexible Production Capacity: We can handle small trial orders starting at 500 pieces and large-scale production runs of 8,000 pieces per month.

Strict Quality Inspection Standards: Our return rate is less than 3%, meeting the stringent workmanship requirements of international brands.

Disadvantages:

Limited product coverage: Lacking experience in men’s and children’s clothing production, we are unable to provide comprehensive product coverage.

Low sampling efficiency: Sample production takes 10-14 days, 50% slower than the industry average.

9.Changda Garment – Best for OEM/ODM Export to Europe

A long-established clothing manufacturer in Jinjiang with 18 years of export experience, it is a core OEM/ODM supplier for European markets including Italy and Spain, with a monthly production capacity of 200,000 pieces. Its equipment comes from Japan and Taiwan.

Main Products:

Basic bulk clothing, including casual wear, sports suits, children’s wear, etc., focusing on durability and compliance.

Advantages:

Complete Compliance: Our products are Oeko-Tex certified and meet European standards for the restriction of hazardous substances.

Strong Production Stability: We have extensive experience in large-scale production and advanced equipment, ensuring consistent batch quality.

Familiarity with the European market: We are familiar with local logistics and customs clearance processes and customer requirements, ensuring efficient communication.

Disadvantages:

Low digitalization: The independent website design is outdated and lacks online consultation and digital sample display functions.

Weak design capabilities: The company primarily focuses on re-editions of classic styles, with few new models updated monthly and insufficient trend sensitivity.

10.Sidifashion – Best for Functional Outdoor Apparel

The company specializes in custom-made high-end fashion women’s apparel, offering both OEM and ODM services. Its clients primarily include chain retailers, wholesalers, and distributors in Australia, Europe, and the United States. Sidi Fashion provides a one-stop service, from design, fabric and accessory sourcing, sampling, to mass production, quality inspection, and export.

Main Products:

Dresses: casual dresses, formal dresses, evening dresses, party dresses. Tops: shirts, jackets. Bottoms: pants.

Advantages:

Small-batch and flexible customization: A key selling point, the minimum order quantity is as low as 100 pieces per color, and mixed sizes are permitted, making it ideal for startup brands and small-volume orders.

Vertical Integration and Capacity Guarantee: Our own factory boasts a monthly production capacity of 50,000-80,000 pieces, staffed by over 100 workers and a professional design, pattern-making, and sample-making team, ensuring effective quality control and lead times.

Strong Design and Development Capabilities: We offer ODM services, with a team of 10 designers and 5 pattern makers, who can develop products based on client sketches or ideas, empowering brand innovation.

Disadvantages:

Relatively Focused Product Categories: The company is highly specialized in women’s apparel. If a client requires customized men’s or children’s clothing, or other specialized categories like functional outdoor apparel, these may not be their specialty.

Standard Sample Production Time: Sample production takes 7-10 days, which is standard in the industry, but may not be fast enough for clients seeking a quick response.

High-end Positioning May Affect Pricing: Focusing on high-end fashion women’s apparel and intricate craftsmanship, such as bead embroidery, may result in higher production costs than smaller and medium-sized factories specializing in basic styles. Pricing requires specific evaluation.