Don't miss our holiday offer - up to 50% OFF!

How to choose the right T-shirt fabric?

Fabric influences your costs, brand positioning, customer experience, and word-of-mouth. Choosing the right fabric composition and GSM ensures your T-shirts meet the needs of your target market. How to choose the fabric for custom women’s t-shirts? We have a reference guide to help you understand T-shirt fabrics and make the most appropriate choice based on your product positioning:

Part One:

The common six types of T-shirt fabrics can be divided into two main categories: the classic series and the functional series.

•The Classic Series (cotton and its upgrade)

1. Ordinary Cotton: An Entry-Level, Low-Cost Option

Advantages: Ordinary cotton (as distinct from premium cotton) is significantly cheaper than other fabrics. The market for ordinary cotton T-shirts is highly mature, and the fabric supply chain is well-established, allowing for significant cost control.

Challenges: Controlling color fastness and shrinkage is challenging, requiring pre-shrinkage treatment and testing.

Recommendation: Suitable for use in situations where uniform clothing is required for a one-time event.

2. Combed Cotton: A Cost-Effective Option

Advantages: Durable, low pilling, smooth and soft. Combing the cotton fibers creates longer, straighter fibers, enhancing the T-shirt’s texture while also making it more breathable and durable. This significantly reduces after-sales issues and helps enhance brand reputation.

Challenges: Cost is 15%-20% higher than regular cotton.

Recommendation: A staple fabric for most brands’ everyday T-shirt collections.

3. Mercerized Cotton: A Premium Option for Light Luxury Series

Advantages: High gloss, excellent color fastness, comfortable and breathable feel. The special sodium hydroxide treatment swells the cotton fibers, giving the fabric a unique luster and enhancing its dye compatibility, resulting in longer-lasting, more vibrant colors.

Challenges: The process is more complex, significantly increasing costs.

Recommendations: Suitable for enhancing brand identity, suitable for casual business or light luxury collections, building a brand image, and clarifying brand positioning.

•The Functional Series (blended and synthetic fibers)

1. Modal / Lyocell (Tencel): An environmentally friendly and comfortable mid-to-high-end fabric.

Advantages: Moisture-wicking, excellent drape, luxurious feel, soft and comfortable, and vibrant colors. Lyocell’s production process perfectly meets environmentally friendly production requirements.

Challenges: Lyocell is more expensive and, compared to other fabrics, is more prone to pilling and warping.

Recommendation: It can be blended with cotton. It is the fabric of choice for creating high-quality mid-to-high-end T-shirt collections.

2. Functional Polyester Fiber: Based on the intended use and needs, functional fabrics are upgraded from basic polyester fibers by applying specialized processing techniques such as cross-sectioning and the addition of ceramic particles.

Advantages: They offer quick-drying, moisture-wicking, high elasticity, and lightweight properties, allowing for marketing strategies based on technical concepts. For example, in sports fabrics, specialized cross-section fiber technology eliminates the solid cylindrical shape through special processing. Grooves on the surface create a capillary effect, rapidly drawing sweat to the outer layer of the fabric for evaporation, achieving moisture absorption and perspiration management.

Challenges: Obviously, functional fabrics require suppliers of specialized functional yarns, which can be costly.

Recommendation: Suitable for professional sports brands.

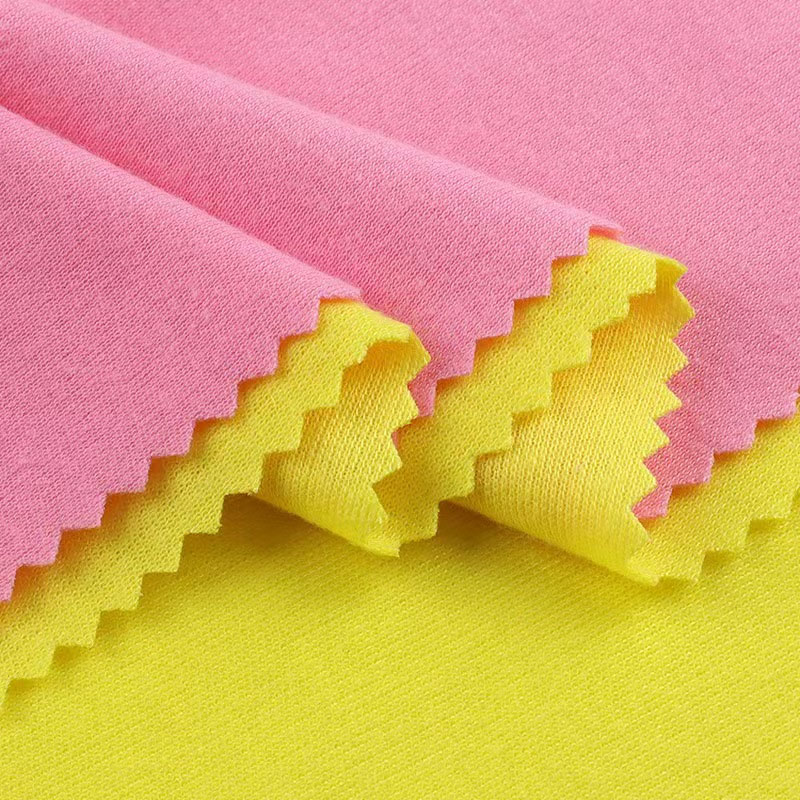

3. Blended fabrics: These combine multiple ingredients. Common blends include cotton / polyester, cotton / modal, and cotton / spandex.

Advantages: They cleverly combine the strengths of each fiber to enhance fabric performance. For example, a cotton/polyester blend offers the breathability and softness of cotton with the wrinkle resistance and durability of polyester.

Challenges: With so many blend options, it can be overwhelming, requiring extensive research to choose the right one.

Part Two:

Parameters affecting T-shirt fabrics

1. GSM (Gram Weight)(185/186/187)

GSM (Gram Weight) is a common term in the apparel industry used to indicate the thickness or weight of a fabric. The GSM for T-shirt fabric ranges from 120 to 220.

A lower GSM indicates a lighter, more breathable fabric, making it ideal for hot summer days or promotional events. A higher GSM indicates a stronger, more durable fabric, making it suitable for streetwear and retail brands.

2. Yarn Count(188/189)

Yarn count refers to the thickness of the yarn used in a fabric. The higher the count, the softer and smoother the fabric.

10-20: Low-count fabrics are thicker and more durable, but not as soft. Suitable for retro style, such as vintage wash t shirts.

20-40: Medium-count fabrics strike a balance between durability and softness. The resulting T-shirts are suitable for casual everyday wear.

40+: High-count fabrics are softer and more comfortable, but less durable and require hand washing. The resulting T-shirts tend to have a more upscale, light-luxury feel.